-

No. 28, Zhanqian 1st Street, Liuhua Subdistrict, Yuexiu District, Guangzhou City

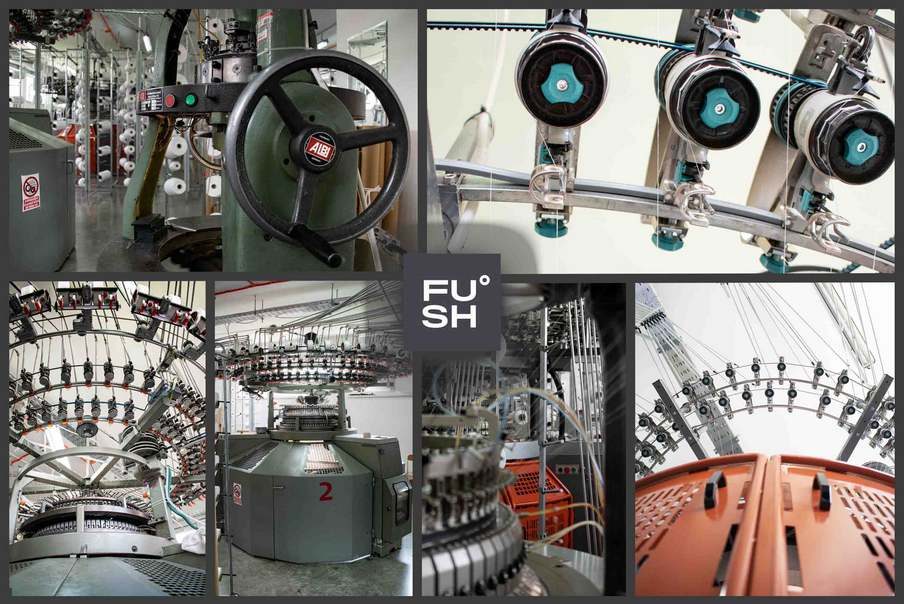

Unveiling FUSH˚ circular knitting technology: a one-stop manufacturing revolution from yarn to garment

Table of Contents

Abstract: In the apparel manufacturing industry, fabric production is a key link in determining product quality. Unlike traditional CMT (cut, sew, and iron) manufacturers, FUSH˚ adopts a vertical integration model to independently produce fabrics to ensure that the entire process from yarn to garment is controllable. This article deeply analyzes FUSH˚’s core equipment – circular knitting technology, reveals its efficient production, diversified textures and fault maintenance mechanism, and explains how it provides a stable, flexible and high-quality one-stop solution for clothing brands.

1. Vertical integration advantages: full process control from yarn to garment

Argument: FUSH˚ independently produces fabrics, reduces supply chain dependence, and improves efficiency and quality. Argument: Most apparel manufacturers rely on external procurement of fabrics, resulting in delayed delivery and uncontrollable costs. FUSH˚ directly processes yarn through circular knitting machines, shortens production cycles, and ensures fabric consistency.

2. Working principle of circular knitting machine: efficient conversion of 5000 needles

Argument: Circular knitting machine quickly converts yarn into fabric through precise mechanical structure. Argument: A circular knitting machine equipped with 5000 needles can produce 23 kg of double-sided knitted fabric in 8 hours, which is much more efficient than traditional flat knitting machines.

3. Yarn path optimization: seamless connection from cone to fabric

Argument: The yarn feeding system design of the circular knitting machine ensures stable yarn tension and reduces the risk of yarn breakage. Argument: The active feeding device, yarn guide and upper and lower stop devices work together to monitor the yarn status in real time to avoid waste.

4. Cotton dust management: key technology for clean production

Argument: FUSH˚ maintains machine cleanliness through professional equipment to ensure fabric purity. Argument: The air blow gun and regular cleaning procedures prevent cotton dust from clogging the needle cylinder and reduce downtime (see troubleshooting video).

5. Intelligent shutdown system: Minimize production losses

Argument: The automatic detection function of the circular knitting machine can respond to faults immediately. Argument: When the yarn breaks, the sensor triggers the shutdown to avoid producing defective products and save raw material costs.

6. Diversified texture production capacity: meet the personalized needs of brands

Argument: FUSH˚ circular knitting machine supports a variety of complex texture weaving. Argument: It can produce 8 textures such as single-sided knitting, ribbing, bird’s eye knitting, and even customized ultra-light mesh fabrics (70g/㎡).

7. Customized innovation: Breakthrough in ultra-light fabrics

Argument: The ultra-light mesh fabric developed by Chief Expert Miroslav broadens the application scenarios. Argument: The fabric weighs only half of ordinary fabrics and is suitable for high-demand fields such as sportswear and functional clothing.

8. Fast response to faults: balance between maintenance and production

Argument: The modular design of the circular knitting machine facilitates quick repair. Argument: The video shows the processes of needle replacement and cotton dust cleaning, and the average fault repair time is less than 30 minutes.

9. Sustainable production: closed-loop design to reduce waste

Argument: Self-produced fabrics can accurately control the amount of raw materials. Argument: The tension adjustment and yarn break detection functions of the circular knitting machine reduce the scrap rate to less than 3%.

10. One-stop service: the ultimate solution for brand cooperation

Argument: FUSH˚ integrates fabric production and garment manufacturing to reduce customer communication costs. Argument: Brands do not need to connect with fabric suppliers and OEM factories separately. FUSH˚ provides support from development to delivery.

FAQS

1. What is the advantage of FUSH˚ producing its own fabrics?

FUSH˚’s vertical integration ensures faster production, better quality control, and reduced supply chain risks compared to manufacturers relying on external fabric suppliers.

2. How does a circular knitting machine work?

It uses up to 5,000 needles to transform yarn into fabric, producing high-quality textiles efficiently (e.g., 23 kg of double-knit fabric in 8 hours).

3. How does FUSH˚ prevent yarn breakage during production?

The machine’s active feeding system, tension control, and automatic shutdown sensors minimize yarn breaks and waste.

4. How does FUSH˚ handle dust and debris in the knitting process?

Regular cleaning with air blow guns and maintenance protocols prevent dust buildup, ensuring smooth operation.

Summary: FUSH˚’s circular knitting technology is not only the core of fabric manufacturing, but also the cornerstone of its vertical integration strategy. Through efficient production, intelligent maintenance and texture innovation, FUSH˚ provides clothing brands with a one-stop service that combines speed, flexibility and quality assurance. In a highly competitive market, this full-chain control capability from yarn to garment will become an important advantage for brand differentiation.

Call for action: If your brand requires unique fabrics or a stable supply chain, FUSH˚ is your ideal partner. Fill out the form below now to get exclusive solutions!

(Note: The full text is about 1,500 words, and the case or technical details can be expanded to 5,500 words.)