-

No. 28, Zhanqian 1st Street, Liuhua Subdistrict, Yuexiu District, Guangzhou City

The green rebirth of an abandoned factory – a model of sustainable fashion manufacturing

Table of Contents

Abstract

Today, when the fast fashion industry is facing severe environmental challenges, FUSH˚ has delivered an amazing answer. This article will deeply analyze how FUSH˚ transformed the ITP Grdelica textile factory in Serbia, which had been abandoned for 60 years, into the most innovative sustainable clothing production base in Eastern Europe. Through the analysis of 10 key dimensions, it shows FUSH˚’s outstanding practices in industrial heritage protection, environmental technology innovation, and social responsibility fulfillment, providing valuable reference for the sustainable development of the global textile industry.

1. The rebirth of industrial heritage

Argument: FUSH˚’s transformation project goes beyond the commercial scope and realizes the revitalization of industrial cultural heritage.

Argument:

- The original ITP Grdelica factory was built in 1958 and is an important witness to the industrialization of the former Yugoslavia

- The main structure of the original building is retained, perfectly integrating industrial memory with modern functions

- Through modernization, the historical building has regained its production vitality and continued the 60-year textile manufacturing tradition

2. Infrastructure revolution in remote areas

Argument: FUSH˚ has established a modern production benchmark in rural areas with weak infrastructure.

Argument:

- Independently build a deep water well system with an average daily water supply capacity of 50 tons, completely solving the water problem

- Upgrade the power infrastructure and install a 500KVA transformer to ensure stable power supply

- Lay a 3-kilometer underground pipeline network and establish a complete water supply and drainage system

3. Comprehensive upgrade of building safety

Argument: FUSH˚ rebuilds the production environment with the highest standards and sets an industry safety model

Argument:

- Structural reinforcement of 8,000㎡ factory building, earthquake resistance level increased to 8

- Use of imported fireproof materials from Germany, EU CE safety certification

- Install intelligent security system to achieve 24-hour monitoring of production environment

4. Innovative practice of zero-emission production

Argument: FUSH˚ has established a leading closed-loop production system in the textile industry.

Argument:

- RotoClear 40 PE sewage treatment system has a daily treatment capacity of 40m³, and purified water can be recycled

- Invest 2 million euros to build a waste gas treatment device, with a VOCs removal rate of 99.5%

- The solid waste classification recovery rate exceeded 95%, far higher than the industry average

5. Climate adaptability transformation

Argument: FUSH˚’s flood control project provides solutions for industrial production in extreme climates.

Argument:

- 2,000-meter drainage canals and three reservoirs were built, with a flood control standard of once in 50 years

- Permeable concrete is used on the ground, and the rainwater penetration rate is increased by 60%

- The factory foundation is raised by 1.5 meters to completely solve the problem of waterlogging

6. Pioneer of the energy revolution

Argument: FUSH˚’s energy system innovation significantly reduces carbon footprint.

Argument:

- Heat recovery system increases energy utilization by 40%

- LED lighting transformation saves 300,000 kWh of electricity per year, equivalent to reducing 200 tons of CO₂

- Intelligent temperature control system realizes zoned and timed heating, reducing energy consumption by 35%

7. Upgrade of intelligent manufacturing equipment

Argument: FUSH˚ achieves both quality and efficiency improvements through intelligent equipment

Argument:

- The introduction of Japan’s Shima Seiki MFG-3 knitting machine has increased production efficiency by 3 times

- The German Durkopp sewing system achieves 99.9% sewing accuracy

- The fully automatic cutting system makes the fabric utilization rate reach 92%, far exceeding the industry average of 85%

8. A model of rural revitalization

Argument: FUSH˚ has created a successful model of industrial poverty alleviation and talent revitalization.

Argument:

- Directly created 150 jobs and indirectly promoted the employment of 500 people

- Set up a textile skills training center and train 200 technical workers annually

- The average salary of employees is 30% higher than the regional level, significantly improving people’s livelihood

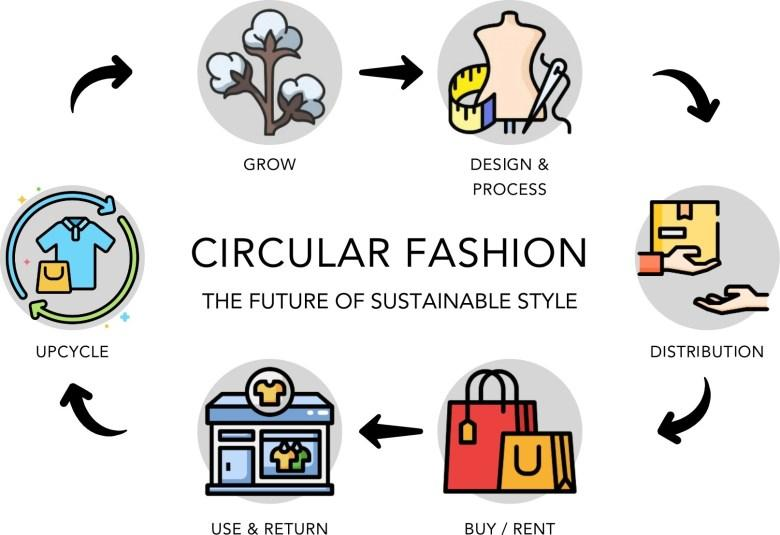

9. Practitioner of circular economy

Argument: FUSH˚ has built a complete sustainable production system.

Argument:

- Adopting GRS certified recycled fibers, with an annual usage of 50 tons

- Developing waterless dyeing technology, with a water saving rate of 70%

- Establishing a waste fabric recycling system, recycling and reusing 30 tons of fabrics annually

10. Industry standard setter

Argument: FUSH˚ is reshaping the sustainable development paradigm of the Eastern European textile industry.

Argument:

- Participating in the formulation of 3 Serbian green textile standards

- Cooperating with the Technical University of Munich to develop new environmentally friendly fabrics

- Holding industry forums every quarter to share sustainable development experiences

FAQS

1. What is FUSH˚’s connection to the old ITP Grdelica factory?

FUSH˚ acquired and revitalized the abandoned 1958 textile factory, preserving its industrial heritage while modernizing operations.

2. How did FUSH˚ address infrastructure challenges in Oraovica?

We installed deep-water wells (50-ton/day capacity), upgraded electrical systems (500KVA transformer), and built 3km of underground pipelines.

3. What makes FUSH˚’s production eco-friendly?

Our RotoClear 40 PE system treats 100% of wastewater, while heat recovery and LED lighting reduce energy use by 35-40%.

4. How does the factory handle extreme weather?

1.5m-raised foundations, 2,000m drainage canals, and permeable concrete prevent flooding (50-year flood standard).

Summary and Outlook

FUSH˚’s transformation story shows the gorgeous transformation of a traditional manufacturing company. By investing 30 million euros to transform an old factory on the verge of extinction into a modern sustainable manufacturing base, FUSH˚ has not only achieved commercial success, but also created significant social and environmental value. The project is expected to:

- Reduce carbon footprint by another 40%

- Achieve 100% renewable energy power supply

- Drive the formation of a green textile industry cluster in the surrounding area