-

No. 28, Zhanqian 1st Street, Liuhua Subdistrict, Yuexiu District, Guangzhou City

FUSH˚ Garment Factory: A Model of Sustainable Expansion and Modern Production

Table of Contents

Abstract

Since its establishment in 2005, FUSH˚ Garment Factory has grown from a small manual tailoring workshop to a modern textile manufacturing center with its steady development strategy and continuous technological upgrades. This article uses 10 core arguments and evidence to deeply analyze how FUSH˚ improves its competitiveness through strategies such as sustainable expansion, automation upgrade, and supply chain optimization, while also exploring its unique advantages in customized clothing production, textile machinery application, and brand cooperation. The article finally summarizes FUSH˚’s successful experience to provide a reference for entrepreneurs and brands in the clothing industry.

1. Transformation from manual production to automated manufacturing

FUSH˚ initially relied only on manual cutting and external OEM, which limited its production efficiency. After 2017, it introduced the Orox Flexo Tailor Combo cutting and spreading machine to achieve cutting automation, greatly improving production speed and accuracy.

2. Successful practice of sustainable expansion strategy

FUSH˚ adopts a gradual development model and only expanded for the first time 12 years later to ensure stable funds and orders and avoid the risks brought by blind growth.

3. Renovation of old factory buildings and space optimization

The abandoned furniture store was transformed into a modern factory, and the cutting, sewing, printing, warehousing and other areas were replanned to maximize the use of space and improve the efficiency of the production process.

4. Breakthrough in independent printing capabilities

In the early days, it relied on external printing. After relocation, an independent printing department was established to reduce supply chain dependence, shorten delivery cycle, and improve customized production capabilities.

5. Improvement of warehousing capacity to ensure production stability

The new factory added a large storage room to ensure sufficient raw materials, avoid production delays caused by supply chain interruptions, and improve customer order fulfillment rate.

6. Acquisition of old textile mills to achieve vertical integration

In 2017, the acquisition of ITP Grdelica textile mill, despite the challenges of transformation, ultimately achieved sewing autonomy, reduced reliance on outsourcing, and enhanced quality control capabilities.

7. Standardization of production processes and efficiency improvement

By optimizing cutting, sewing, printing, packaging and other links, FUSH˚ established a standardized assembly line to ensure high-quality production and meet the OEM needs of international brands.

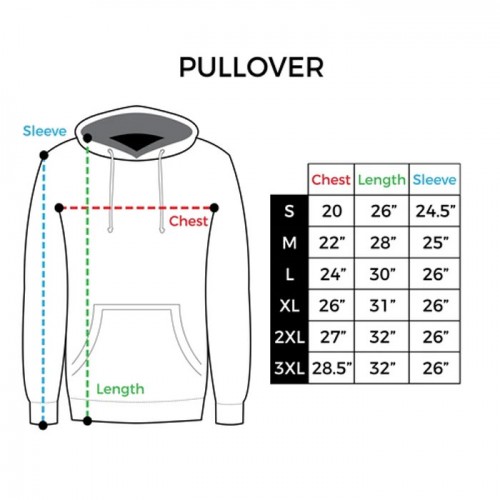

8. Core competitiveness of customized production

FUSH˚ focuses on customized hoodies and sportswear production, providing flexible small batch order services to help emerging clothing brands get started quickly.

9. Textile machinery upgrades promote industry competitiveness

Continuous investment in advanced equipment, such as automated cutting tables and digital printing machines, enables FUSH˚ to maintain technological leadership in textile manufacturing.

10. Combination of global vision and localized production

Based in Serbia, we take advantage of local labor cost advantages and connect with international market demand to provide global customers with cost-effective clothing manufacturing solutions.

FAQS

1. What services does FUSH˚ offer?

FUSH˚ specializes in custom clothing production, including hoodies, sportswear, and OEM manufacturing for brands.

2. How does FUSH˚ ensure sustainable growth?

We focus on gradual expansion, automation upgrades, and supply chain optimization to maintain stability.

3. What machinery does FUSH˚ use for production?

We utilize advanced equipment like Orox Flexo Tailor Combo cutting machines and digital printers for precision and efficiency.

4. Can FUSH˚ handle small-batch orders?

Yes, we support flexible small-batch production, ideal for startups and emerging brands.

Summary

The success of FUSH˚ clothing factory stems from robust expansion strategy, automation upgrade, supply chain optimization and customized production capabilities. Its development history proves that sustainable growth is more conducive to the long-term stability of enterprises than blind expansion. For clothing brand entrepreneurs, FUSH˚ provides a reliable cooperation model – from fabric selection, cutting and sewing to printing and packaging, the whole process is controllable to ensure quality and efficiency.

If you need to know customized clothing production, textile machinery application or brand OEM cooperation, please fill in the contact form to get exclusive quotes and production plans.

Keywords: clothing factory, sustainable expansion, customized hoodie, sportswear manufacturer, textile machinery, Orox cutting machine, brand OEM, supply chain optimization, automated production, old factory transformation