-

No. 28, Zhanqian 1st Street, Liuhua Subdistrict, Yuexiu District, Guangzhou City

From plastic bottles to high-performance sportswear: How recycled polyester fiber reshapes the fashion industry

Table of Contents

Abstract: Against the backdrop of global environmental awareness, recycled polyester fiber (rPET) is leading the revolutionary change in the sportswear industry. This article will deeply analyze the value of the entire industry chain of rPET from raw material recycling to finished product manufacturing, and systematically demonstrate its outstanding advantages in environmental benefits, product performance, and market competitiveness through 10 core arguments. The article combines FUSH˚’s innovative practices to provide brands with a feasible solution for sustainable transformation.

1. Closed-loop economy: Give waste plastics a new lease of life

Argument: The rPET yarn used by FUSH˚ can be converted into 16 500ml plastic bottles per kilogram, and the GRS certification of its British supplier Martin Bunzl ensures that 100% of the raw materials come from post-consumer recycled plastics, forming a complete resource recycling system.

2. Carbon footprint reduction: a pragmatic choice to address the climate crisis

Argument: Compared with virgin polyester fibers, the production process of rPET reduces energy consumption by 59% and carbon dioxide emissions by 32%, which is in line with the emission reduction targets of the Paris Agreement.

3. Performance breakthrough: redefining the standard of sportswear

Argument: The patented knitting technology developed by FUSH˚ makes rPET fabrics both ultra-light (only 85g/m²) and excellent breathability. After testing, its water evaporation rate is 40% faster than conventional fabrics.

4. Microplastic solution: a manifestation of industry responsibility

Argument: By integrating the German GUPPYFRIEND laundry bag and the Italian FILTROL microplastic filter, FUSH˚ provides customers with a complete microplastic management solution, reducing 92% of fiber shedding during washing.

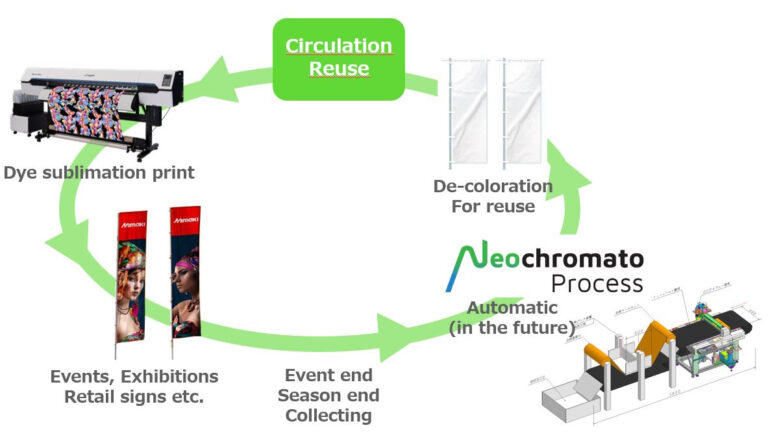

5. Dyeing Revolution: Environmentally friendly innovation that subverts tradition

Argument: Epson SureColor SC-F9400H water-based ink system achieves zero wastewater discharge, and color fastness reaches level 4-5 (ISO 105-C06 standard), far exceeding traditional dyeing and finishing processes.

6. Transparent supply chain: Rebuilding consumer trust

Argument: FUSH˚’s blockchain traceability system allows customers to view real-time data from plastic bottle recycling to garment delivery, including energy and water consumption in each production link.

7. Lightweight design: Improve sports performance

Argument: According to professional athlete tests, FUSH˚’s rPET competition suits reduce the load by 210 grams (based on a full set of equipment) compared to traditional products, significantly improving sports performance.

8. Certification system: reducing compliance risks

Argument: In addition to GRS certification, FUSH˚’s OEKO-TEX® STANDARD 100 certification ensures that the product does not contain 328 hazardous substances and meets the requirements of EU REACH regulations.

9. Economic benefits: guarantee of long-term competitiveness

Argument: Although the cost of rPET raw materials is 15-20% higher, the brand premium can reach 30-50%, and the EU plastic tax (€800/ton) will gradually eliminate the price gap.

10. Industrial upgrading: promoting industry transformation

Argument: FUSH˚’s vertical integration model (from yarn to garment) shortens the delivery cycle to 21 days and reduces transportation carbon emissions by 58%.

FAQS

1. What is rPET?

rPET is recycled polyester fiber made from post-consumer plastic waste, primarily plastic bottles.

2. How many plastic bottles make one T-shirt?

Approximately 16 recycled 500ml plastic bottles are used per kilogram of rPET fabric.

3. Is rPET better for the environment?

Yes – it reduces energy use by 59% and CO₂ emissions by 32% compared to virgin polyester.

4. Does rPET perform as well as regular polyester?

Yes – FUSH˚’s rPET offers superior breathability (40% faster drying) and lighter weight (85g/m²).

5. How is microplastic shedding addressed?

Solutions like GUPPYFRIEND washing bags can reduce fiber shedding by 92% during laundry.

Summary: Recycled polyester fiber is reshaping the value chain of the sportswear industry, and its significance goes far beyond simple material substitution. From the practice of FUSH˚, it can be seen that through technological innovation (such as water-based dyeing), system certification (GRS/OEKO-TEX) and business model innovation (closed-loop production), rPET has achieved the perfect unity of environmental protection and commercial value. In the face of the upcoming EU Green New Deal and consumer awakening, early layout of the rPET supply chain will become the key to the brand’s future success. This is not a choice, but an industrial revolution that must be grasped.

Keywords: Closed-loop economy, carbon footprint, microplastic management, water-based dyeing, blockchain traceability, lightweight design, vertical integration, GRS certification, industrial upgrading, FUSH˚ innovation