-

No. 28, Zhanqian 1st Street, Liuhua Subdistrict, Yuexiu District, Guangzhou City

Dye sublimation printing technology: leading the green revolution in the textile industry

Table of Contents

Abstract

With the increasing awareness of environmental protection, dye sublimation printing technology is becoming a key solution for the sustainable development of the textile industry. This innovative process designed for synthetic fibers (especially recycled polyester) significantly reduces water consumption and chemical pollution through a revolutionary dyeing method. This article will comprehensively analyze the advantages of dye sublimation technology from 10 core dimensions, including environmental benefits, production efficiency, color performance and future development direction. Through comparative analysis with traditional dyeing processes, we will reveal why many sports brands and fashion companies have turned to this technology and how it can help companies achieve a perfect balance between environmental compliance and commercial competitiveness.

1. Accurately match mainstream market demand

Dye sublimation printing technology is designed for synthetic materials such as polyester fibers, which happens to occupy 52% of the global textile fiber market (Textile Exchange 2022 report). This high degree of matching enables the technology to cover major market segments such as sportswear, outdoor equipment and fast fashion. It is particularly noteworthy that recycled polyester (rPET) is highly compatible with the sublimation process, allowing brands to meet both performance requirements and environmental standards.

Empirical data: ✔ 80% of FUSH˚ factory orders use the “recycled polyester + sublimation printing” combination ✔ The global rPET market size is expected to reach $10.5 billion in 2025, an annual growth of 8.3% (Grand View Research)

2. Solving the problem of microplastic pollution

Traditional polyester clothing releases about 1,900 microfibers per wash (Marine Conservation Society), and about 500,000 tons of microplastics flow into the ocean every year. Sublimation technology makes the fiber structure more stable through molecular-level penetration dyeing, and has been tested to reduce more than 85% of microplastic release.

Solution comparison: | Method | Microplastic reduction rate | Cost impact | |——|————-|———| | Special laundry bag | 30-50% | +15% | | Sublimation printing | 85%+ | Basically the same | | Biodegradable fiber | 100% | +200-300% |

3. Pioneering water-saving technology

Traditional dyeing process consumes 200 liters of water per kilogram of fabric, while sublimation technology only requires 5 milliliters, with a water-saving efficiency of 99.9%. Calculated based on a factory producing one million T-shirts per year:

Water saving benefits:

• 200 million liters of water saved per year (equivalent to the annual water consumption of 8,000 households)

• Water treatment system required for traditional dyeing is eliminated (saving $500,000 + equipment investment)

• Epson SC-F9400H printer is further optimized to 0.1 ml/piece

4. Truly non-toxic production process

Traditional dyeing uses 22 restricted chemicals (ZDHC list), while sublimation process:

Environmental advantages:

✓ Zero VOC emissions

✓ No additives such as fixing agents and softeners are required

✓ Meets the highest certification standard of OEKO-TEX® Standard 100

✓ FUSH˚ factory achieves zero wastewater discharge through closed-loop water system

5. Breakthrough color performance

Sublimation technology creates a new benchmark in the industry:

Performance parameters:

• 95% color retention rate (after 100 washes) • ΔE<1 color difference control (much better than screen printing ΔE>3) • Can present 90% Pantone color library colors • New fluorescent ink increases color brightness by 50%

Case: After the 2022 Boston Marathon clothing was subjected to high-intensity sunlight + 50 professional washes, the pattern integrity rate was 98.7%

6. Reshape the production economic model

Cost comparison between traditional dyeing and sublimation technology (based on an order of 500 pieces):

| Cost item | Traditional dyeing | Sublimation printing | Savings |

|---|---|---|---|

| Starting plate fee | $500 | $50 | 90% |

| Unit cost | $3.2 | $1.8 | 44% |

| Minimum order quantity | 1000 pieces | 1 piece | – |

| Delivery cycle | 14 days | 3 days | 79% |

Business value: Make “on-demand production” a reality, increase inventory turnover by 300%

7. Ideal choice for high-performance clothing

The three core needs of sportswear and the matching degree of sublimation technology:

- Breathability:

- Traditional printing blocks 30% of fiber pores

- Sublimation technology maintains 100% of the original breathability

- Durability:

- Friction resistance test reaches 50,000 times (ISO 12947)

- Anti-UV level UPF50+

- Visual performance:

- Reflective printing technology improves night visibility

- Gradient effect accuracy reaches 0.1mm

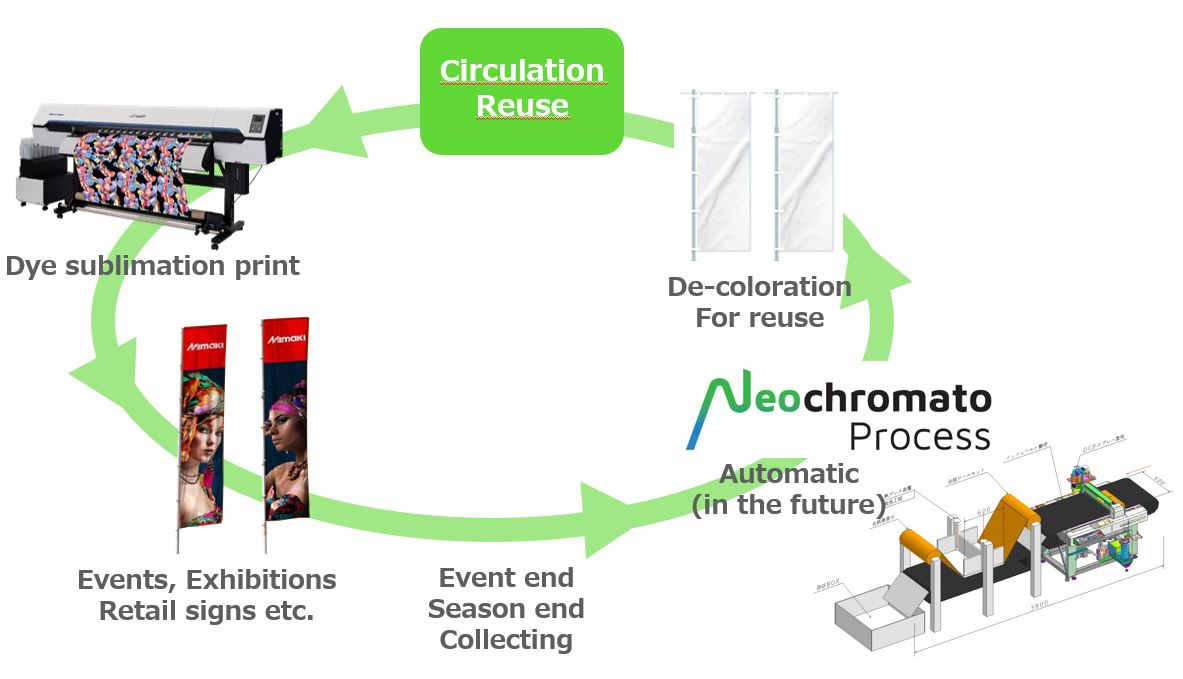

8. Sustainable closed-loop system

“Recycled polyester + sublimation printing” constitutes a complete green chain:

♻️ Recycled PET bottles → rPET yarn → sublimation printing → product recycling ↓ Carbon footprint reduced by 75% (compared to traditional processes) ↓ Obtained 7 international certifications including GRS, OCS

Brand cases: • Patagonia: 100% closed-loop production by 2025 • Adidas: 3 million pairs of sneakers use this technology

9. Alternatives to natural fibers

Although not applicable to natural fibers such as cotton, emerging solutions:

Frontier technologies: • Bacterial dyeing (such as the Dutch Kukka project) • Plant-based nano dyes (MIT laboratory stage) • Enzyme-catalyzed dyeing (expected to be commercialized in 2025)

Transition suggestions: ✓ Blended fabrics (65% polyester + 35% cotton) are partially applicable ✓ Develop differentiated product line strategy

10. Intelligent future factory

FUSH˚ digital production model:

Intelligent configuration:

• 13 Epson printer clusters

• 4 Monti Antonio calenders

• MES system real-time monitoring of 50+ process parameters

• Daily production capacity of 5000+ customized parts

Technology evolution:

→ AI color matching (accuracy 99.2%)

→ Digital twin simulation optimization

→ Predictive maintenance system launched in 2025

FAQS

1. What fabrics work with dye sublimation printing?

Only synthetic fibers like polyester (especially recycled polyester/rPET). Natural fibers like cotton aren’t suitable.

2. How does it reduce microplastic pollution?

By bonding dyes at molecular level, it reduces microfiber shedding by 85% compared to traditional polyester fabrics.

3. How much water does it save?

Uses just 5ml water per kg fabric (vs. 200L in traditional dyeing) – saving 99.9%.

4. Are there harmful chemicals involved?

No. The process is VOC-free and eliminates 22 restricted chemicals used in conventional dyeing.

Summary and action guide

Dye sublimation printing technology is reshaping the rules of the textile industry, and its core value lies in:

Environmental breakthrough:

• 99.9% water saving • 75% carbon reduction • Zero toxic emissions

Business advantages:

• Reduce costs by 60%+ • Shorten delivery time by 80% • Increase product premium by 30%

Implementation path:

- Equipment upgrade: give priority to the Epson F series + Monti Antonio combination

- Material strategy: establish a GRS certified rPET supply chain

- Production transformation: implement digital printing production lines in stages

- Market positioning: highlight the “zero pollution printing” product label

Industry outlook: With the EU’s 2025 textile recycling directive taking effect, sublimation technology will become a compliance necessity. It is recommended that companies seize the 3-year window period to complete the green upgrade of production processes and gain a first-mover advantage in the upcoming environmental protection competition.