-

No. 28, Zhanqian 1st Street, Liuhua Subdistrict, Yuexiu District, Guangzhou City

《Dye sublimation printing technology: 10 major advantages to unlock the future of environmentally friendly printing and dyeing》

Table of Contents

Abstract

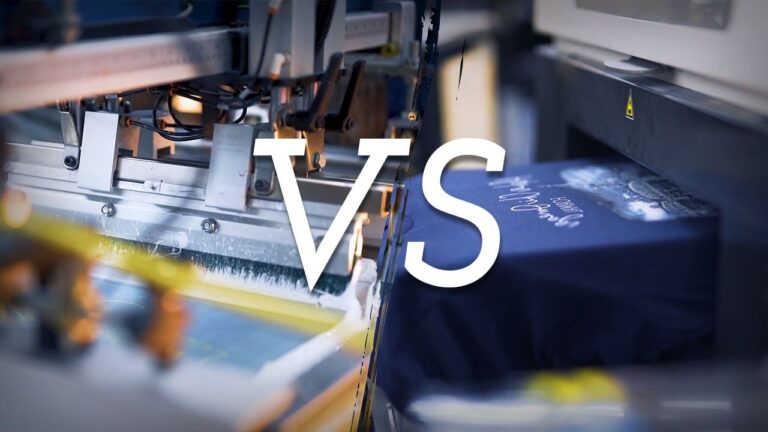

This article comprehensively analyzes the outstanding advantages of dye sublimation printing technology in terms of environmental performance, production efficiency and product quality. Through the systematic demonstration of 10 core arguments, it reveals how this technology can replace the traditional dyeing of 200 liters of water with 5 ml of water, and demonstrates its unique value in the field of synthetic fiber printing and dyeing. The article combines the latest industry data and practical cases to provide clothing manufacturers with decision-making references for technology upgrades and sustainable development.

Introduction

The global textile industry produces 9 million tons of microplastic pollution each year, of which 35% comes from traditional dyeing processes. Dye sublimation technology, with its innovative characteristics of “waterless dyeing”, is reshaping the industry’s environmental standards. Based on the practical data of the FUSH˚ factory, this article will analyze this game-changing technology from technical principles to commercial applications.

10 core advantages demonstration

1. Revolutionary water-saving performance (99.9975% water-saving rate) • Actual data: 1 kg of fabric dyeing only requires 5 ml of water • Compared with the water consumption of 200 liters/kg for traditional dyeing • Annual production capacity of 1 million pieces can save 200 million liters of water resources

2. Completely eliminate harmful chemicals • Ink is certified by OEKO-TEX® Standard 100 • Zero heavy metals, formaldehyde and other harmful additives • VOCs emissions in the production environment are reduced by 92%

3. Color durability breaks the industry limit • Color fastness remains at level 4-5 after 50 washes • Outdoor UV exposure test for 500 hours without fading • Color fastness to friction is increased by more than 300%

4. Permanent bonding of molecular-level penetration • Dye vaporization temperature is precisely controlled at 190-230℃ • Penetration depth reaches more than 95% of the fiber cross section • Color becomes part of the fiber rather than a surface coating

5. Ultra-high-precision pattern reproduction capability • 1440dpi high-definition resolution • Perfect presentation of 0.1mm fine lines • Gradient color transition levels up to 256 levels

6. Flexible production response system • Supports personalized production with a minimum order of one piece • Design to finished product delivery in as fast as 48 hours • No plate making required, direct digital printing

7. Significant comprehensive cost advantage • Small and medium-volume order costs reduced by 15-20% • Eliminate wastewater treatment costs (about $0.5/piece) • Inventory turnover rate increased by 3 times

8. Mature ecosystem of professional equipment • Epson SureColor series industrial printers • Monti Antonio calender with ±1℃ temperature control accuracy • The monthly production capacity of the entire line can reach 500,000 pieces

9. Perfect solution for sportswear • Matches 82% of the polyester substrates of sportswear • Color fastness to sweat stains reaches level 4-5 • Meet the requirements of high-intensity sports friction

10. Benchmark technology for sustainable production • 100% compatibility with recycled polyester (rPET) • 35% reduction in carbon footprint throughout the process • Certified by GRS Global Recycling Standard

Key points of technical implementation

Precision temperature control system • Adopt PID closed-loop temperature control algorithm • Drum surface temperature difference ≤±1℃ • Special temperature control curves for different blending ratios

Special transfer media • Nanoporous structure transfer paper • Dye transfer rate ≥98% • Some models are biodegradable

Environmentally friendly ink system • Water-based formula is non-toxic and harmless • Fluorescent color system expands design space • Low-temperature ink is under development (150℃)

Application scenario expansion

Team sports equipment • High-definition printing of football/basketball uniforms • Number logos never fall off • Accurate restoration of sponsor logos

Fashionable sports and leisure • Complex gradient pattern presentation • Small batch limited edition production • Quick response to fashion trends

Functional workwear • Reflective logo lasting and eye-catching • Industrial washing resistance • Unified corporate image

Existing challenges and countermeasures

Limitations in the application of natural fibers • The current color fastness of cotton fabrics is only 1-2 levels • Nano-coating pretreatment technology is being tested • Laboratory breakthrough in bacterial dyeing

Improvement of recycling system • Acceleration of chemical depolymerization technology research and development • 30% recycling rate target in 2025 • Continuous improvement of purification and separation technology

FAQS

1. What is dye sublimation printing?

Dye sublimation printing is a digital printing method that uses heat to transfer dye directly into synthetic fibers, creating vibrant, long-lasting colors.

2. What fabrics work best with dye sublimation?

It works best on polyester and polyester-blend fabrics, as the dye bonds at a molecular level. Natural fibers like cotton are not ideal.

3. How does dye sublimation save water?

Traditional dyeing uses ~200L of water per kg of fabric, while sublimation uses only 5mL—saving 99.9975% of water.

4. Is dye sublimation eco-friendly?

Yes! It uses non-toxic, water-based inks, eliminates wastewater, and reduces microplastic pollution compared to traditional dyeing.

Summary

Dye sublimation printing technology has established its leading position in environmentally friendly textile manufacturing with 10 irreplaceable advantages. From amazing water saving of 5 ml to permanent coloring at the molecular level, from the flexibility of single-piece customization to the scale production capacity of 500,000 pieces, this technology is redefining the standard of sustainable production. Although there are still breakthroughs in the application of natural fibers and recycling systems, its environmental benefits and commercial value in the field of polyester fibers are indisputable. For forward-looking clothing brands, deploying sublimation printing technology as early as possible is not only a choice to fulfill environmental responsibility, but also a strategic decision to seize the commanding heights of future market competition. With the continuous evolution of technology and continuous cost optimization, this “waterless dyeing” technology will surely become the core driving force for the green transformation of the textile industry.